What your other bearing suppliers wouldn’t want you to know!

China is world factory. Chinese Bearing is taking bigger and bigger share in the world market. But for most distributors and users, they don’t know much about Chinese bearing market and is totally unaware of tricks factories can play. Repeatedly attracted by cheaper bearing and got cheated, victims complaint about their suppliers and blamed on Chinese bearing too.

Findbearing is telling you the truth that other bearing suppliers would not want you to know. This is the real Chinese bearings, quality depends on choice.

What are the quality differences between factories?

How could factory make extra money by saving material (stealing materal)?

How could a trading company earns extra profit?

Generally, quality of Chinese bearings varies from factory to factor, from area to area, even from time to time

It is not a standard, P0 (or ABEC-1, Z1 etc) that can tell you everything about the bearing quality. As it is the same thing, “GCr15” does not mean material quality.

See What influence the bearing quality?

So What are the quality differences between factories?

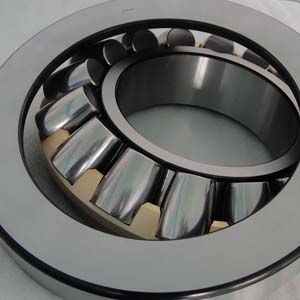

Bearing problems can be dimentions, outlook, tolerance, clearance, noise, material impurity, designing(structure), heat treatment, sealing, roundness, rust, magnetism etc. A good factory need to have some elementary conditions to avoid before mentioned problems. Simply see from the equipment, workshop enviroment, then oversee the management, quality control equipment (including standard parts and maintenance), professional knowledge in their production range, we know whether the factory has the prerequisite of doing a certain quality level.

Do not be mislead by saying like ” We are capable of doing some quality or some series”. It is important to be aware of what exactly the factory has been producing. As many factories are doing trading business, it makes no sense comparing the equipment or management.

A good responsible factory with complete equipments will generally control quality in a certain level. Management and attitute is the key point for the stability of the bearing quality.

Findbearing has visited hundreds of factories and is considering different factors that may influence the bearing quality. A group of usual factories has been selected out to be our “reliable” supplier, the supplying system is always updated when further information is recorded during visitation, quality inspection, customer feedback and news shared in bearing factory cycle.

How could factory make extra money by saving material (stealing materal)?

Some adepts may have heard of the saying “stealing material”. This is very porpular and sometime it is even harder to find the material of the original design. (Thickness of pipes). This revise is based on design, could be seen by samples or parts drawing. Normal assembling drawing will be exactly the right thing. And it is life length that are influenced and could be used fine in most cases.

This is very porpular in small deep groove ball bearings which has been produced by pipes that than forged parts.

And also very porpular for large size bearings, factory could revised the drawing, using as less brass as possible, truning some grooves on brass cage or even use more rollers took the place of brass.

More easier for factories choosing a cheaper parts.

Steel ball with the same G10 Z4 lable varies greatly on prices. It can be over 50% difference from two regular factories.

But to think factory can change steel ball from G10 to G16.

Heat treament, improve efficience, doing things faster or put rings of different size in same oven could also save a lot cost in the long run.

When production is busy, factories or salesman can trade on some bearings, it’s easy money and not cost. Most sound Chinese brands are doing this, why not? Since SKF is also buying.

When you know What influence the bearing quality? You know factory has so many choices to do a bearing better or worse. It is so easy to get cheaper parts and sometimes a conpulsory to do so in order to get the orders. Only when this is the reponsible factory and value you as their important customer, they will think about giving you the good solutions.

Do not reply on factory’s conscience when you paid a high price and it is the better to have someone oversee quality for you.

How could a trading company earns extra profit?

Many trading companies are pretending to be a factory, cost is concealing source and cost.

More porpular is to sactter inquires, compare all factories they think possible and find out the cheapest, pressing old factory or simply risk on the cheaper ones. Some with conscience may has it inspected.

Still a lot companies simply use the cheapest source and trading on the bearings of the lowest rank.

Findbearings is working with “reliable” factories only and provides selective inspection service. Quality first, then quality/cost rate, do not work on risky bearings of the lowest rank. For any items that we are not so familiar with, the inspection will be added as a must.

This is informative article.