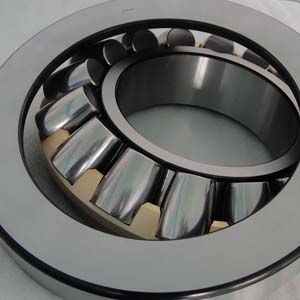

There are generally two types of bearing rust, surface rust and chemical corrosion.

Surface rust can be seen easily.

Chemical corrosion is harder to distinguish, chemical cell formed on bearing surface, looks like point rust, it actually rust deep. The bearing ring is easily broken when running with load.

As to why Bearing rust, it could be caused by many reasons.

Rust during usage.

- Contact of water or corrosive substance.

- Inappropriate lubricant

- water vapor freeze-up

- stalling in high temperature moisture environment

Rust before customer receiving the goods.

- Improper operation, touched by visitors/inspection people by bare hands/fingers. Salt on hands may greatly damage the anti-rust effect.

This is very likely happened in factories when individual bearing found rusted on surface. - Duration of validity for normal domestic anti-rust oil is 2~3years, bad anti-rust oil may contain impurity and even water inside.

Choosing a proper anti-rust oil is important. FUCHS anti-rust oil is strongly recommended by Findbearing.com.

- Damaged during transportation. Container truck is always preferred during long distance transportation to avoid raining.

As bearing will be useless when soaked by water, avoid raining is very important. A good protection by the bearing packing would do some help too. - In south east China, there is a raining period for nearly a month. The weather is very wet. Moisture comes all directions, even from the ground.

Findbearing.com has been trying to avoid annual bulk quantity stock purchase in this period. And anti-rust requirement is always being emphasized and special clause added to factories for better protection. - Good storage and maintenance.

Findbearing.com has inspection people to do the job. If the bearings were not maintained, simply opening and looking could easily found those produced long time ago. Generally, most factories Findbearing.com is working with, is controlling rust well.

When bearing is going to contact water or corrosive substance or will expose to air directly. Special treatment is a must.

- Electrophoresis(Good effect, bearing anti-rust treatment )Electrophoresis, bearing anti-rust treatment.

- Galvanize(Yellow zincing, white zincing, now yellow zincing is not allowed in Europe)white zincing, zinc platedyellow zincing bearing, zinc plated, galvanize

- Painting. (Mostly used on Housings)

- Parkerizing(Does some effect, looks beautiful)

- Using different material. Stainless steel, ceramic etc.stainless steel bearingCeramic bearing.

Ceramic bearing

Electrophoresis treatment

White Zinc plated

stainless steel bearing

Leave a Reply