Factory selection

Selection of proper bearing factories will be key important to ensure the quality stability. Responsible factories usually think further development, would not ruin their reputation chasing profit in short period. Using original designing, Choosing high quality material, using high grade roller/ball, even the usage of high quality anti-rust oil etc., all manifest the responsibility of the factory.

As bearing quality could be influenced by too many factors, besides from the objective conditions, findbearing.com is do all means to understand a factory, understand their boss and their way of doing things. Most mistakes are made by man, not the machines. A good management by the factory leaders could avoid many quality problems. Here we are not talking about certificate.

Do not fully trust in any kind of certificates in China. We won’t say ISO2000, TS16949 are useless. Factories might indeed learn something in the process of getting the certificate, but in real operation, they couldn’t carry out the regulations completely, or simply just two management.

For most factories, certificate is “pay to get” stuff from many service company, could be a good advertisement instead of its original meaning.

Findbearing.com is taking an overall evaluation on each factory, constantly upgrading the factory information. Only those long time co-operated with stable quality will become our Reliable factories.

Additional selective quality checking

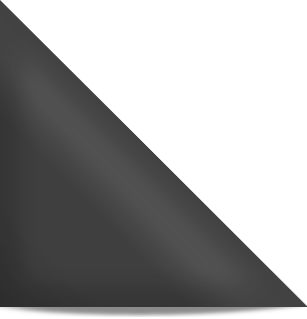

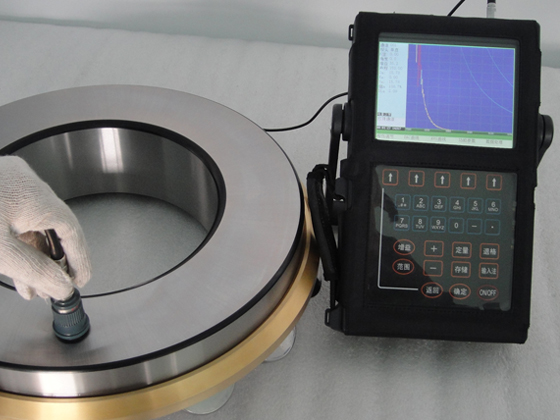

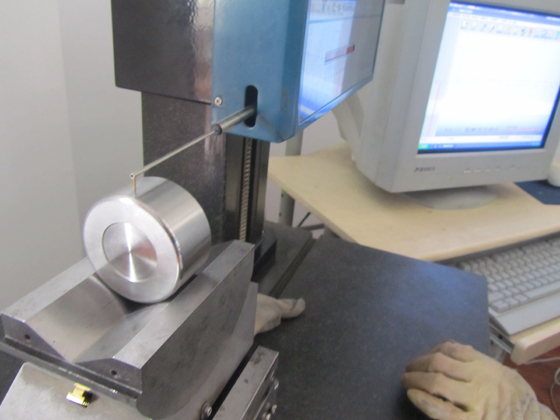

In addition to factory selection and control, Findbearing provides additional selective quality inspection service, cost very low in Cixi area. When customer wish to risk choosing some factories cheap but not so reliable to us, the additional quality checking service/charge will be mandatory.

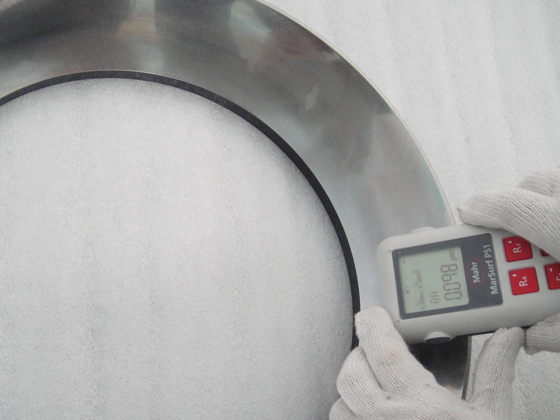

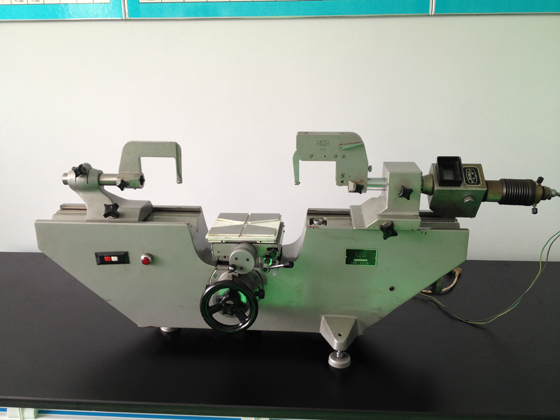

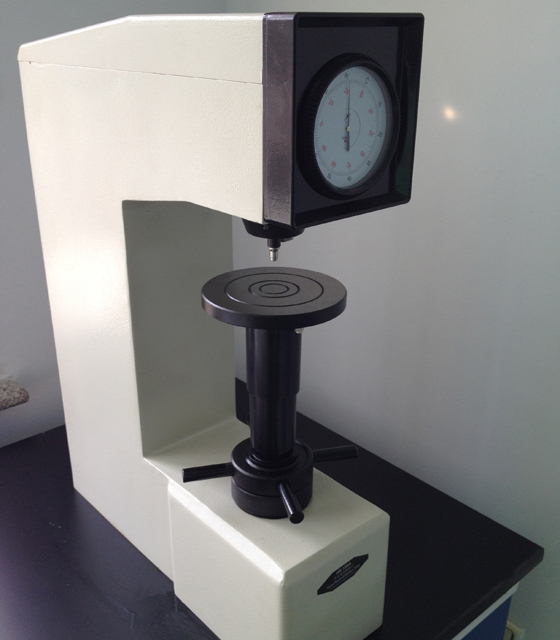

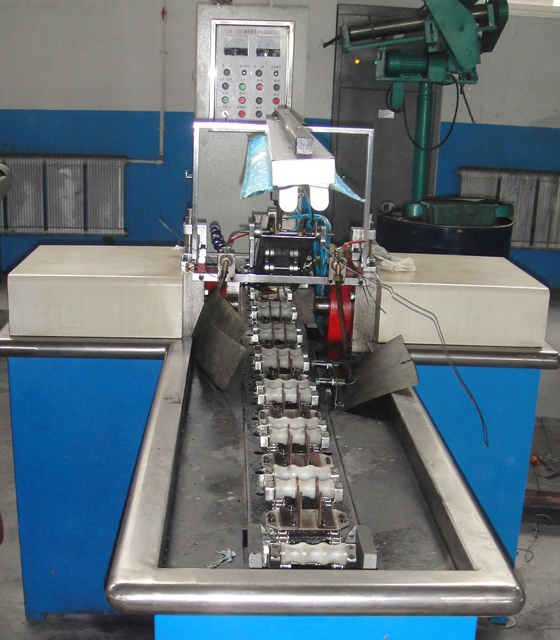

Findbearing has special technicians doing quality checking with inspection equipment. Thus, quality of the product can be strictly controlled. Here are some inspection video regarding the clearance,hardness, inner ring diameter, material and residual magnetism checking.